- Browse Categories

-

Tempered Glass

- Laminated Glass

- Insulated Glass

- Curved Glass

- Glass Application

- Elevator Glass

- Curtain Wall Glass

- Floor Glass

- Table Top Glass

- Roof Glass

- Photo Frame Glass

- Window and Door Glass

- Balustrade Glass

- Shower Door Glass

- Decorative Glass

- PDLC Smart Glass

- U-Glass

- Clear Float Glass

- Tinted Float Glass

- Reflective Glass

- Low Iron Glass

- Low E Glass

- Mirror Glass

- Aluminum Veneer

- Anti-reflective Glass

- Laminated Glass

- Certifications

-

- Subscribe

-

Get email updates on new products

- News

-

- How does a two way mirror work?

- Possible causes of defects in laminated glass and solutions

- The most comprehensive knowledge of the LOW-E glass

- Difference between heat-strengthened glass and fully tempered safety glass

- How to realize glass hot bending, cold bending or lamination bending?

- Difference between PVB laminated glass and SGP laminated glass

- Difference between PVB laminated glass and EVA laminated glass

- The packaging solutions for building glass

- What’s wired glass?

- The news of the Chinese shipping market and glass market

- Contact Us

-

SHENZHEN JIMY GLASS CO., LIMITED SHENKENG INDUSTRIAL ZONE, SHENFENG ROAD, LIUYUE, HENGGANG, SHENZHEN, CHINA TEL: 0086 755 28211334 / 0086 755 8934... Contact Now

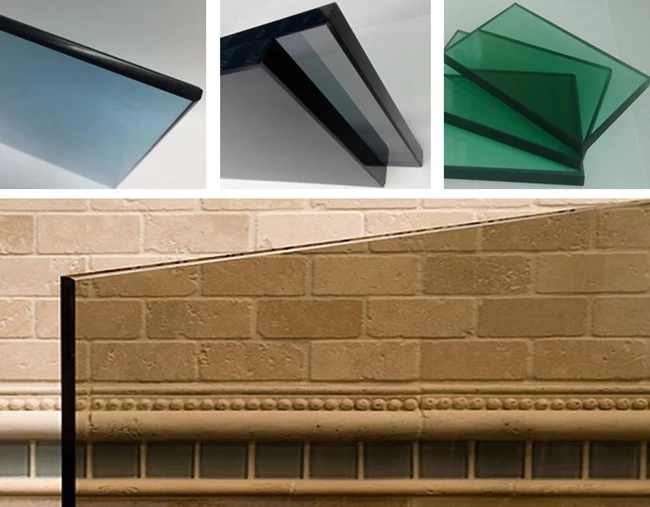

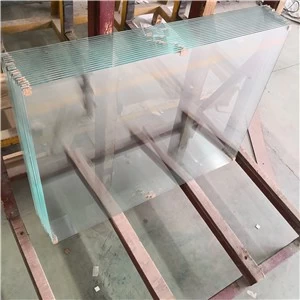

Export bronze blue green grey black colored tinted security tempered glass 4mm 5mm 6mm 8mm 10mm 12mm

- Shape: Flat and curved

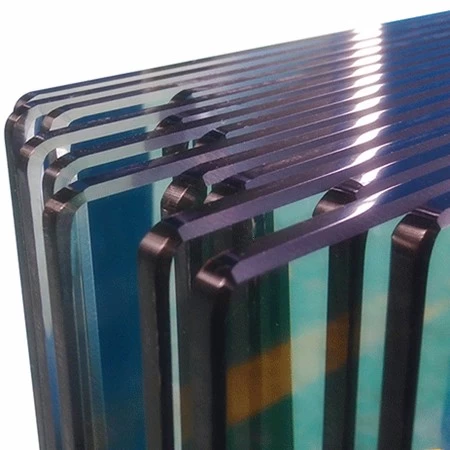

- Thickness: 4mm 5mm 6mm 8mm 10mm 12mm

- Size: Max 2440x3660mm, any customized size could be produced

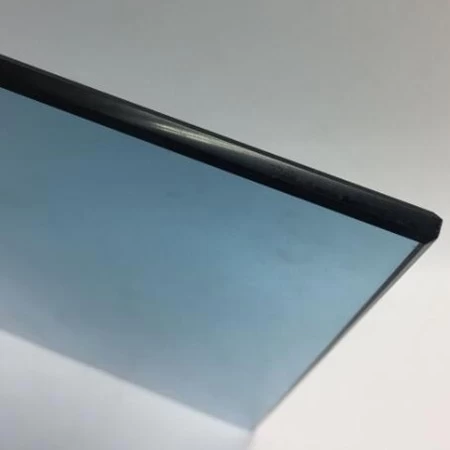

- Color: Bronze, golden, light blue, dark blue, F-green, dark green, light grey, dark grey, black

- Processing: Polished edges, drill holes, cut notches, screen printing, etching, etc.

- Production time: Within 15 days after order is confirmed.

4mm 5mm 6mm 8mm 10mm 12mm colored safety tempered glass

Colored tempered glass introduction

Colored decorative safety tempered glass, is produced by heating color tinted float glass to over 600°C and cooling it rapidly, which locks the outer surfaces of the glass in a state of high compression, and the center of the glass in compensating tension, to improve the glass carrying capacity, enhance the glass performance of wind resistance, impact resistance, heat resistance, etc.

Colored toughened glass advantages

• High strength. Based on same thickness, the color tempered glass impact resistance strength and bending resistance strength is 3-5 times higher than the ordinary color float glass, so it is not easy to break.

• High safety. When the color tinted tempered glass is destroyed by external forces, the debris will be similar to the honeycomb-like small obtuse angle particles, not easy to cause harm to the human.

• Heat stability. Color heat resistant tempered glass has good thermal stability, can withstand 3 times higher temperature difference than the ordinary float glass, can withstand 200°C temperature difference.

• Excellent decorative effect. With different bright and enduring color, the color decorative toughened glass not only could absorb sun radiation and ultraviolet rays, to make the interior more comfortable, but also could greatly enhance the appearance of the building, make the building more attractive.

Colored toughened glass disadvantages

• After tempering, the tempered glass can not further process like custom cut size, drill holes, cut notches, all the required process should be done before tempering.

• Although the strength of tempered glass is stronger than ordinary float glass, but the tempered glass has the possibility of self-explosion, but the ordinary glass does not have this possibility.

• Tempered glass surface will be uneven (especially for the jumbo size tempered glass), and with a slight thickness thinning. The reason for the thinning is because when the glass after the hot melt softening and after a strong wind to make it quickly cooling, the glass inside the crystal gap becomes smaller, the pressure becomes larger, so the glass thickness will be thinner after tempering.

Colored toughened glass specifications

• Shape: Flat and curved

• Thickness: 4mm 5mm 6mm 8mm 10mm 12mm

• Size: Max 2440x3660mm, any customized size could be produced

• Color: Bronze, golden, light blue, dark blue, F-green, dark green, light grey, dark grey, black

• Processing: Polished edges, drill holes, cut notches, screen printing, etching should be done before tempering, after tempering, the glass could use to make safety color tempered laminated glass, color tempered insulated glass

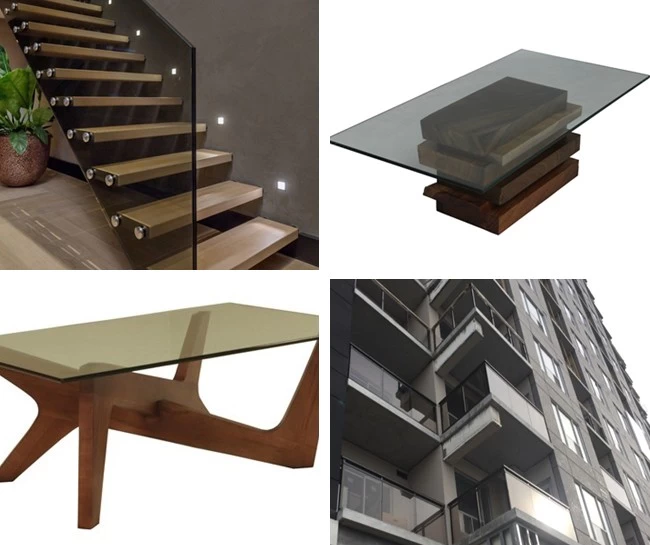

Colored tempered glass application

The monolithic tinted safety tempered glass, or color toughened laminated glass, or color safety tempered insulated glass, is more and more widely used around us:

• For building like glass doors and windows, glass curtain wall, indoor partition glass, ceiling glass, sightseeing elevator glass, glass fence, etc.

• For home appliance like glass oven doors, glass refrigerator doors, glass cutting boards, etc.

• For furniture like glass table tops, glass shelves, glass cabinet doors, etc.

• Many others.

Colored tempered glass introduction

Colored decorative safety tempered glass, is produced by heating color tinted float glass to over 600°C and cooling it rapidly, which locks the outer surfaces of the glass in a state of high compression, and the center of the glass in compensating tension, to improve the glass carrying capacity, enhance the glass performance of wind resistance, impact resistance, heat resistance, etc.

Colored toughened glass advantages

• High strength. Based on same thickness, the color tempered glass impact resistance strength and bending resistance strength is 3-5 times higher than the ordinary color float glass, so it is not easy to break.

• High safety. When the color tinted tempered glass is destroyed by external forces, the debris will be similar to the honeycomb-like small obtuse angle particles, not easy to cause harm to the human.

• Heat stability. Color heat resistant tempered glass has good thermal stability, can withstand 3 times higher temperature difference than the ordinary float glass, can withstand 200°C temperature difference.

• Excellent decorative effect. With different bright and enduring color, the color decorative toughened glass not only could absorb sun radiation and ultraviolet rays, to make the interior more comfortable, but also could greatly enhance the appearance of the building, make the building more attractive.

Colored toughened glass disadvantages

• After tempering, the tempered glass can not further process like custom cut size, drill holes, cut notches, all the required process should be done before tempering.

• Although the strength of tempered glass is stronger than ordinary float glass, but the tempered glass has the possibility of self-explosion, but the ordinary glass does not have this possibility.

• Tempered glass surface will be uneven (especially for the jumbo size tempered glass), and with a slight thickness thinning. The reason for the thinning is because when the glass after the hot melt softening and after a strong wind to make it quickly cooling, the glass inside the crystal gap becomes smaller, the pressure becomes larger, so the glass thickness will be thinner after tempering.

Colored toughened glass specifications

• Shape: Flat and curved

• Thickness: 4mm 5mm 6mm 8mm 10mm 12mm

• Size: Max 2440x3660mm, any customized size could be produced

• Color: Bronze, golden, light blue, dark blue, F-green, dark green, light grey, dark grey, black

• Processing: Polished edges, drill holes, cut notches, screen printing, etching should be done before tempering, after tempering, the glass could use to make safety color tempered laminated glass, color tempered insulated glass

Colored tempered glass application

The monolithic tinted safety tempered glass, or color toughened laminated glass, or color safety tempered insulated glass, is more and more widely used around us:

• For building like glass doors and windows, glass curtain wall, indoor partition glass, ceiling glass, sightseeing elevator glass, glass fence, etc.

• For home appliance like glass oven doors, glass refrigerator doors, glass cutting boards, etc.

• For furniture like glass table tops, glass shelves, glass cabinet doors, etc.

• Many others.