- Browse Categories

-

Tempered Glass

- Laminated Glass

- Insulated Glass

- Curved Glass

- Glass Application

- Elevator Glass

- Curtain Wall Glass

- Floor Glass

- Table Top Glass

- Roof Glass

- Photo Frame Glass

- Window and Door Glass

- Balustrade Glass

- Shower Door Glass

- Decorative Glass

- PDLC Smart Glass

- U-Glass

- Clear Float Glass

- Tinted Float Glass

- Reflective Glass

- Low Iron Glass

- Low E Glass

- Mirror Glass

- Aluminum Veneer

- Anti-reflective Glass

- Laminated Glass

- Certifications

-

- Subscribe

-

Get email updates on new products

- News

-

- How does a two way mirror work?

- Possible causes of defects in laminated glass and solutions

- Difference between heat-strengthened glass and fully tempered safety glass

- The most comprehensive knowledge of the LOW-E glass

- How to realize glass hot bending, cold bending or lamination bending?

- Difference between PVB laminated glass and SGP laminated glass

- Difference between PVB laminated glass and EVA laminated glass

- The packaging solutions for building glass

- What’s wired glass?

- The news of the Chinese shipping market and glass market

- Contact Us

-

SHENZHEN JIMY GLASS CO., LIMITED SHENKENG INDUSTRIAL ZONE, SHENFENG ROAD, LIUYUE, HENGGANG, SHENZHEN, CHINA TEL: 0086 755 28211334 / 0086 755 8934... Contact Now

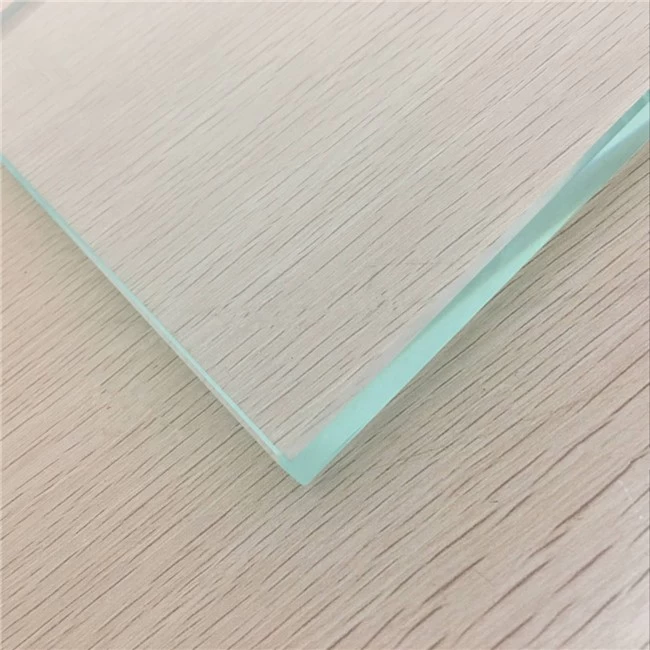

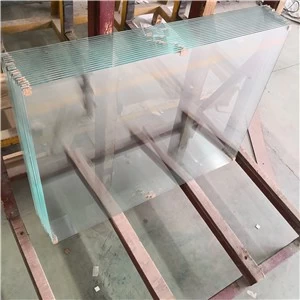

10mm ultra clear toughened glass factory,China 10mm low iron tempered glass,10mm super white hardened glass price

- Super high light transmittance, reach to 90%

- Super high strength, near five times of normal float glass

- High security-human harmless when broken

- Maximum size could reach to 3000*8000mm

- Polish edges, cut to size, drill holes, etc. must be done before tempering

- used as safety railing glass, aquarium glass, store front wall glass, kitchen splashback glass

- Production time within 15days after order is confirmed

- All the glass pack in strong plywood crates with metal belt

CE Certificate 10mm Ultra Clear Tempered Glass Manufacturer

About Ultra Clear Tempered Glass

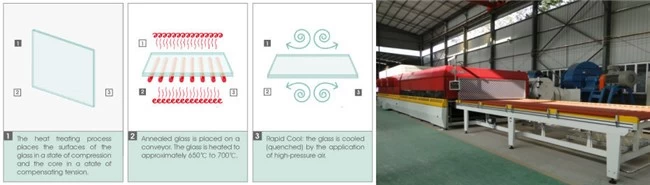

Ultra Clear Tempered glass, also Low Iron Toughened Glass, is fabricated by heating ultra clear low iron glass to over 600°C and cooling it rapidly, which locks the outer surfaces of the glass in a state of high compression, and the core or center of the glass in compensating tension. It is a safety glass which is used when strength, thermal resistance and safety are important considerations.

Ultra Clear Tempered Glass Characteristic

High Strength

The super white tempered glass performs well in resisting bending and hitting owing to its high strength which is about five times that of normal float glass. It is able to withstand a surface pressure of 95Mpa.

High Safety

When the tempered glass is broken, it turns into alveolate granules with obtuse angles, which guarantee safety to make sure human harmless, and the toughening process greatly reduces the risk of thermal breakage to ensure less loss.

Heat Stability

The tempered glass is capable of withstanding a temperature change of 250 to 320℃ while normal annealed glass can only bear 20 to 100℃.

High Transparency

Super high transparency and a neutral color making it the ideal glass where high visibility and clarity are required.

Performance Comparison

|

Items |

Tempered Glass |

Semi-tempered Glass |

Normal annealed glass |

|

Safety |

Best |

General |

None |

|

Intensity |

152Mpa |

/ |

30-90Mpa |

|

Thermal Stability |

250-320℃ |

100℃ |

20-100℃ |

|

Surface Stress |

95Mpa |

24-69Mpa |

/ |

|

Broken State |

Obtuse-angle grain |

Shooting-broken |

Sharp |

10mm Ultra Clear Tempered Glass Specification

10mm ultra clear toughened glass available size: Maximum 3000*8000mm, Minimum 150*300mm

All the processing done on the 10mm super clear toughened glass like polish edges, cut to size, drill holes, cut notches, cutouts, screen printing, acid etched, etc. must be done before tempering.

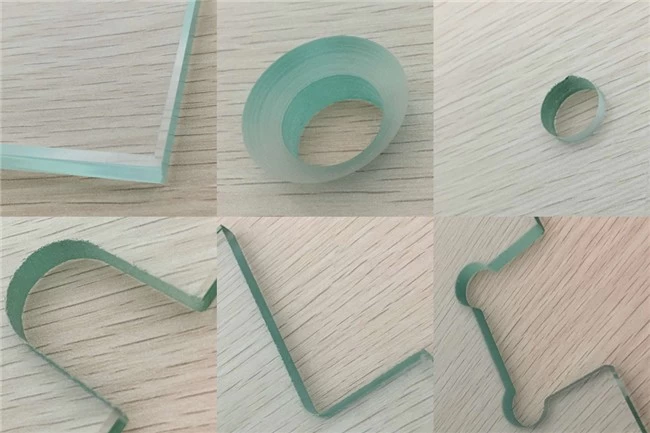

Edge work

Any edges could be done perfectly on 10mm ultra clear toughened glass, like flat polished edge (T edge), pencil edge (C edge), beveled edge, ogee edge, matt edge, corner round edge.

Holes and notches

Tempered glass can be supplied with drilled holes (no matter straight or conical) and cut notches. We will consider hole and notch locations and size according to your drawings. Please kindly check below details:

|

Glass edge to nearest point of hole |

10mm clear toughened glass should not have holes located any closer than 2 times the thickness of the glass. |

|

Glass corner to nearest point of hole |

Holes should not be located any closer than 6.5 times the thickness of the 10mm clear toughened glass. |

|

Dimension of holes |

The minimum dimension of a hole should not be less than the thickness of the glass. The maximum dimension of the hole should not be more than 1/3 the narrowest dimension of the piece. |

|

Notches and cutouts |

All must have a fillet with radius equal to, or greater than the thickness of the glass. |

Shapes

Except rectangle 10mm ultra clear toughened glass, Jimy Glass also could do shape 12mm ultra clear toughened glass, like round low iron hardened glass, Trapezoid super white reinforced glass, parallel ultra clear safety glass, etc.

10mm Ultra Clear Tempered Glass Application

Most often use as safety railing glass, high transparency aquarium glass, store front wall glass, kitchen splashback glass, etc., and use to make 21.52mm low iron laminated glass to use as security stair railing glass, jumbo size balcony glass, elevator glass, etc., and make 10+10+10mm anti-slip laminated glass for floor, etc.

Quality Standard

In accordance with EN12150 European tempered glass standard

In accordance with ASTM1048 American Standard

In accordance with GB 9963-1998 Tempered Glass Standard

In accordance with GB 17981-1999 Chinese Standard Tempered and Heat-Strengthened Glass

Pass Chinese Safety Glass Compulsory Certification (CCC), IGCC, CSI.

Tempered Glass Processing

Difference Between Normal Clear Tempered Glass and Low Iron Tempered Glass